|

|

|

|

|

|

|

| ||||||||||

|

|

|

|

|

|

|

||||

| ||||||||||

|

|

|

|

|

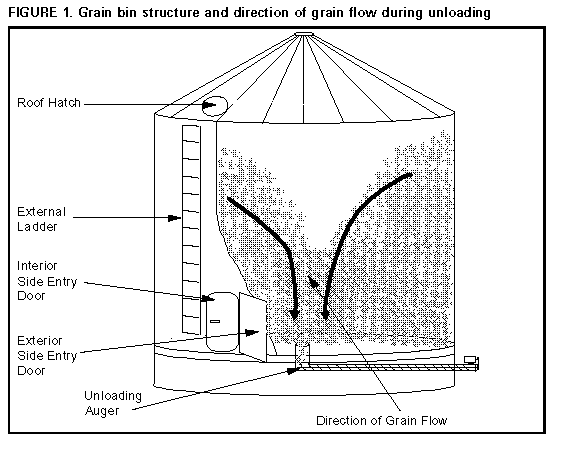

Persons using assistive technology might not be able to fully access information in this file. For assistance, please send e-mail to: [email protected]. Type 508 Accommodation and the title of the report in the subject line of e-mail. Suffocations in Grain Bins -- Minnesota, 1992-1995Suffocation in flowing grain is the most common cause of death associated with grain storage structures in the United States (1,2): during 1985-1989, suffocation accounted for 49 grain- and silage-handling-associated fatalities (3). During 1992-1995, nine persons in Minnesota died in separate incidents from asphyxiation after becoming engulfed in flowing grain within a grain storage structure (Figure_1). The Minnesota Fatality Assessment and Control Evaluation program (FACE), a program sponsored by CDC's National Institute for Occupational Safety and Health (NIOSH) *, was notified of the incidents by the state Occupational Safety and Health Administration (MN-OSHA), Minnesota Extension Services, and a newspaper clipping service. This report describes the investigation of three of these incidents by FACE, summarizes surveillance for grain bin suffocations during 1992-1995, and provides recommendations to prevent suffocations associated with grain storage bins. Case Reports Incident 1. On December 17, 1992, a 32-year-old man working at a commercial grain elevator became engulfed in 60,000 bushels (1000 bushels=1240 cubic feet) of corn that were being emptied from the bottom of the bin by a grain auger **. He had entered the bin through the roof hatch to dislodge crusted grain. Co-workers called rescue personnel when he was noted to be absent, and holes were cut in the grain bin walls to accelerate emptying of the bin. The worker's body was recovered near the center of the bin 8 hours after the incident. Employees reported the man had been warned not to enter the bin. Confined-space safety measures, including warning signs on the bin, were in place. Incident 2. On September 11, 1994, a 44-year-old farmer was asphyxiated after he became immersed in 6000 bushels of corn being removed from a self-unloading bin. He had entered the bin through the roof hatch to dislodge crusted grain that had blocked the auger intake. Several minutes later, a co-worker noted he was missing and shut off the auger. He was pulled out of the grain from above by family members, resuscitation efforts were initiated, and emergency personnel were called. He was transported to a local hospital and pronounced dead approximately 1 hour after having entered the bin. Incident 3. On July 11, 1995, a 13-year-old boy became submerged in 2500 bushels of corn in a grain bin as the grain was being loaded into a truck by a portable auger. He had been seen observing the unloading process from a point near the roof opening of the bin; his father, who was working near the truck below, noticed he was no longer visible. Rescue personnel cut holes in the lower portion of the bin to allow the grain to spill out. The boy was then extracted and transported to the hospital but died on July 13. Surveillance for Suffocations Associated with Grain Bins Since 1992, the Minnesota Department of Health has compiled surveillance and field investigation data about selected work-related agricultural fatalities through FACE. FACE collects epidemiologic data from multiple sources, including police reports, on-site investigations, and MN-OSHA, regarding selected occupational fatalities and develops and disseminates prevention recommendations to address identified risks. During 1992-1995, nine persons in Minnesota suffocated in grain bins. All nine were males aged 13-71 years (mean: 36 years). Six of the incidents occurred on family-owned farms, and three occurred at commercial grain elevators. Grain was being unloaded or removed from the involved storage bins in eight incidents and was being added to the bin in one case. The amount of grain involved in the incidents ranged from 600 to 60,000 bushels, and grain types included corn (six incidents), soybeans (two), and wheat (one). Because none of the engulfments and subsequent suffocations were witnessed, recognition of most cases and initiation of rescue efforts were delayed. Reported by: GL Wahl, MS, SE Folken, DJ Boyle, DVM, DL Parker, MD, Minnesota Dept of Health. Div of Safety Research, National Institute for Occupational Safety and Health, CDC. Editorial NoteEditorial Note: The findings in this report indicate that suffocations in grain bins are a continuing source of preventable occupationally related deaths among workers in the agriculture industry. CDC's National Traumatic Occupational Fatalities (NTOF) surveillance data from 1980 through 1992 contain death-certificate reports of 88 farm workers killed by engulfment in grain or other agriculture produce stored in bins or silos, and the Census of Fatal Occupational Injuries (CFOI) (maintained by the Bureau of Labor Statistics) contain an additional 33 reports of deaths associated with engulfment in grain bins for 1993 through 1994 (NIOSH, unpublished data, 1996) ***. No reliable estimates are available for nonfatal incidents. Most grain storage bins are round, flat-bottomed structures with capacities of 20,000-100,000 bushels of grain (1,2); many older bins on farms are smaller and may hold less than or equal to 5000 bushels (Figure_1). Most bins on farms are filled through a hatch in the roof and emptied through a hole in the center of the floor (4). The mechanical augers used to unload bins can move grain at rates of up to 3000 cubic feet per hour (1,2), and a person can become completely submerged in the flowing grain in 8 seconds (1,2). Because grain bin interior doors are designed to open inward, side doors cannot be opened during rescue efforts when grain levels are above the entry doors. Suffocations in grain bins usually occur when bins are being emptied. During emptying, the flowing grain forms an inverted cone with strong enveloping forces, which can quickly draw a person under the surface (Figure_1) (1,2,4-6). A worker walking on stationary grain may sink only 12 inches ****; in comparison, flowing grain has characteristics of quicksand and can rapidly induce immersion (1,2,4,5). Suffocation also can occur if a worker enters a bin containing caked, frozen, or spoiled grain. When such grain is unloaded from below, an overlying crust forms, which can collapse under the weight of a person standing or walking on the crust (1,2,4-6). The average annual number of suffocations associated with grain bins in Minnesota increased from 1.3 during 1985-1991 to 2.3 during 1992-1995 (Minnesota Department of Health, unpublished data, 1996). During January-June 1996, three suffocations were reported in Minnesota. This increase may reflect factors such as the increased storage capacities of bins, faster speeds of grain-handling equipment, automation that enables operators to work alone (6), or increased surveillance for agriculture-related deaths. Measures to prevent suffocations associated with grain bins include 1) updating existing grain bins by installing safety features that are now standard for most newly manufactured bins (e.g., installation of permanent inside ladders and warning stickers to alert workers to the hazards of entrapment and suffocation); 2) installing pressure-sensitive indicators on bin walls to allow workers to determine the level of the grain without entering the bin; 3) using epoxy coatings to prevent caked grain from adhering to the inside walls of bins; and 4) encouraging grain bin manufacturers and distributors to review instruction manuals with customers. In addition, NIOSH recommends the following precautions to reduce the risk for suffocation related to immersion in flowing grain (4,7):

Because workers who enter grain bins also may be exposed to the hazards of confined spaces, grain bins should be identified as confined spaces, and workers should follow established confined space entry procedures when entering bins. Anyone entering a bin should wear a safety harness and a lifeline attached to a fixed external anchor point. In addition, a co-worker should be stationed outside the bin whenever a worker enters. Visual contact and/or audible communication should be maintained between the worker in the bin and the co-worker at all times. When workers enter bins equipped with ventilation fans, the fans should be turned on before entry; when ventilation fans are operating, they can provide airflow through the stored grain and into the bin atmosphere, providing a safer confined-space atmosphere for entry by workers. References

* Minnesota is one of 14 states (Alaska, California, Colorado, Indiana, Iowa, Kentucky, Maryland, Massachusetts, Minnesota, Missouri, Nebraska, New Jersey, Wisconsin, and Wyoming) that receive funding from NIOSH for state FACE programs. ** A large, corkscrew-like device used to move dry materials. *** Data collected through NTOF surveillance include injury-related deaths of workers aged greater than or equal to 16 years that are clearly identified as being work-related on death certificates. CFOI data are derived from a multisource, nationwide reporting system begun in 1992. **** Some grains, such as flax and millet, cannot support a person even when not flowing. Figure_1  Return to top. Disclaimer All MMWR HTML versions of articles are electronic conversions from ASCII text into HTML. This conversion may have resulted in character translation or format errors in the HTML version. Users should not rely on this HTML document, but are referred to the electronic PDF version and/or the original MMWR paper copy for the official text, figures, and tables. An original paper copy of this issue can be obtained from the Superintendent of Documents, U.S. Government Printing Office (GPO), Washington, DC 20402-9371; telephone: (202) 512-1800. Contact GPO for current prices. **Questions or messages regarding errors in formatting should be addressed to [email protected].Page converted: 09/19/98 |

|||||||||

This page last reviewed 5/2/01

|